IN SIENA, TECHNOLOGY AND INNOVATION IN GLASSWORK

Glass processing is a practice that requires using many specific techniques, a great deal of experience and practical skills. These features are all part of the professional background of skilled workers and technicians employed at Vetreria Il Vetro.

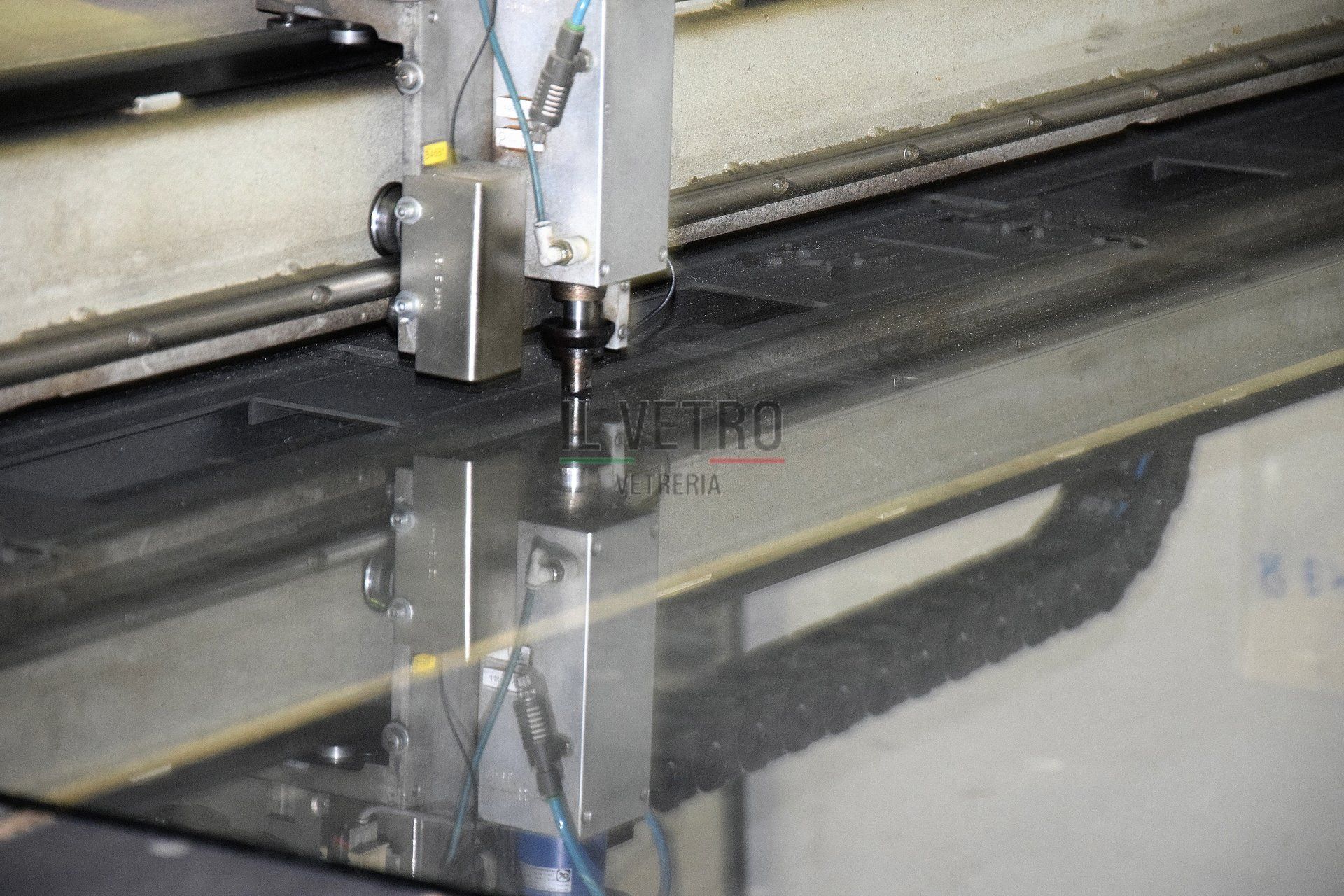

CUT

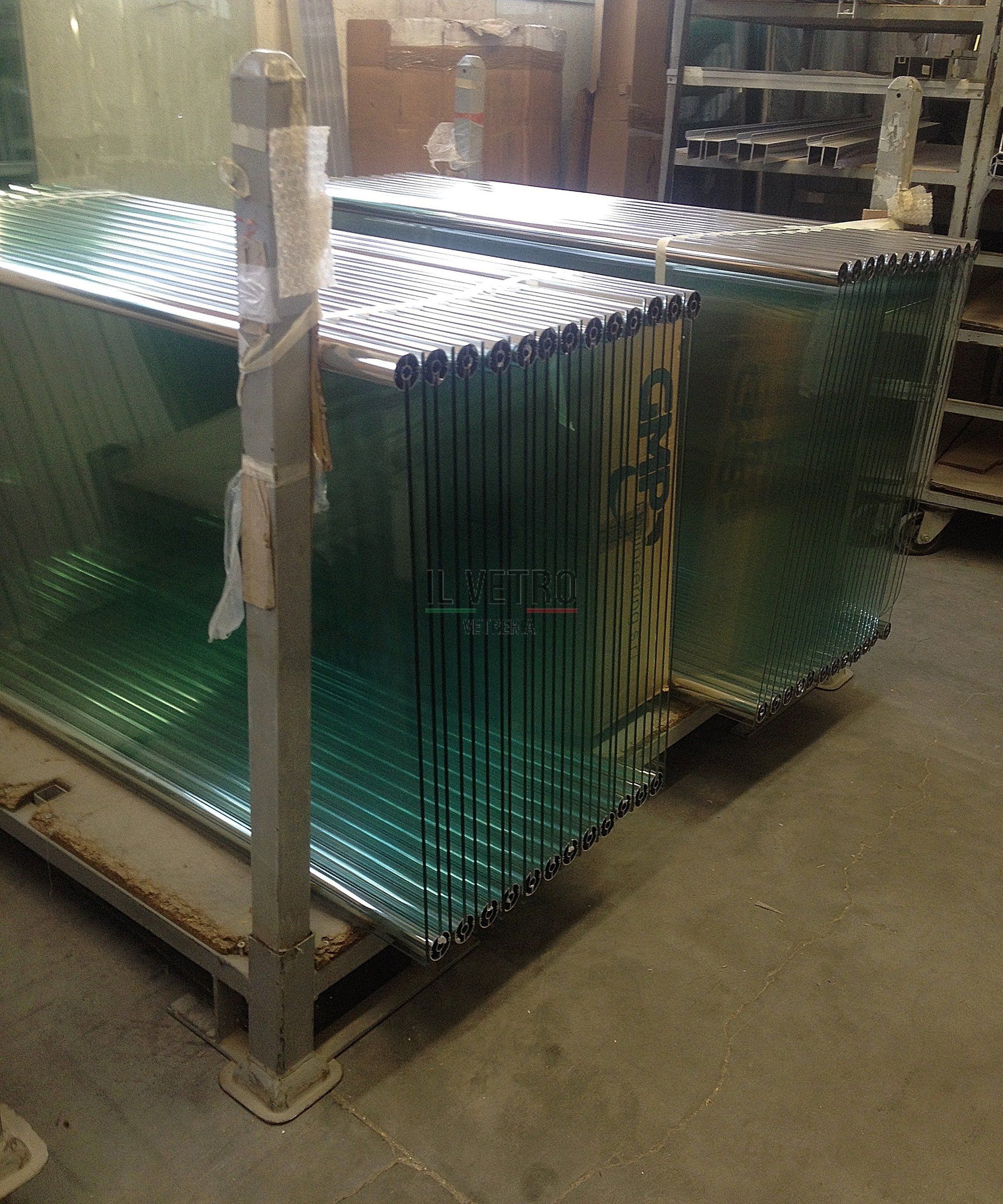

The cut-to-size of the glass slabs is carried out by a numerical controlled mobile stand. The handling of the plates is performed safely, using suitable machines and of the cutting bench that is automatically vertically positioned for the secure placement of the slab. Using a special software, the glass is engraved by a synthetic diamond and then cut-off manually. The laminated glass is made by joining two slabs with a polymeric film; on this type of glass, the cutting is performed first on both slabs then the film is cut with a special cutter.

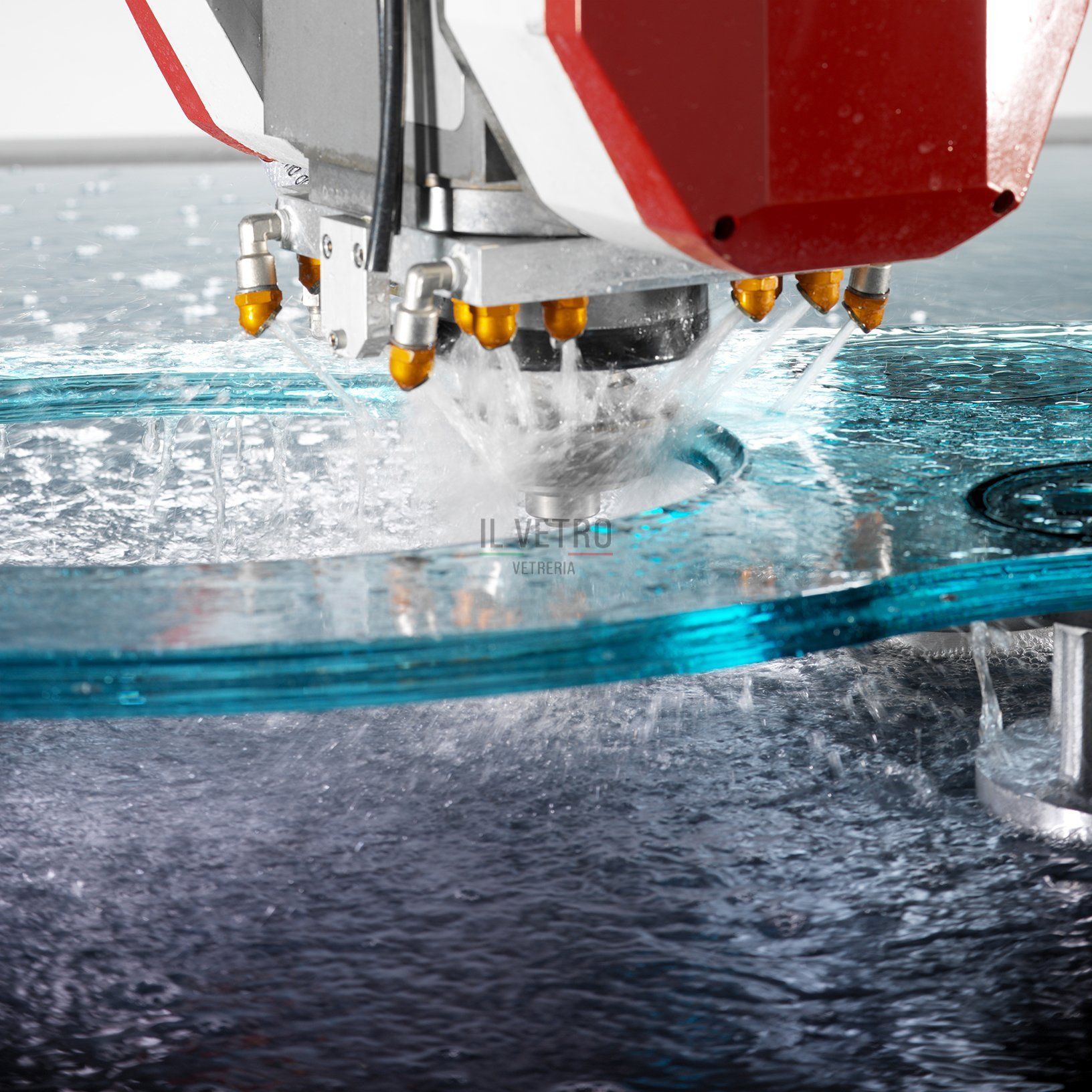

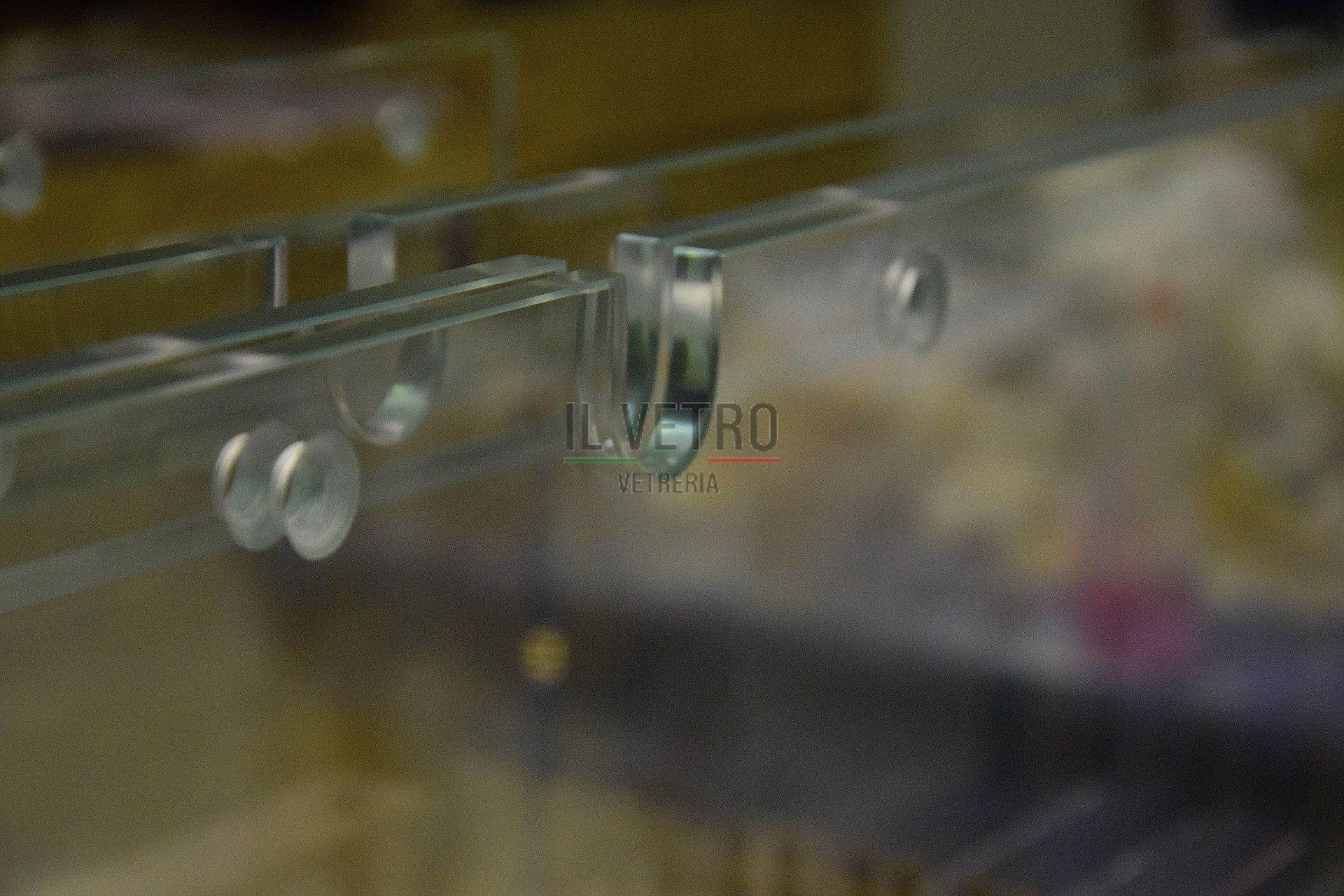

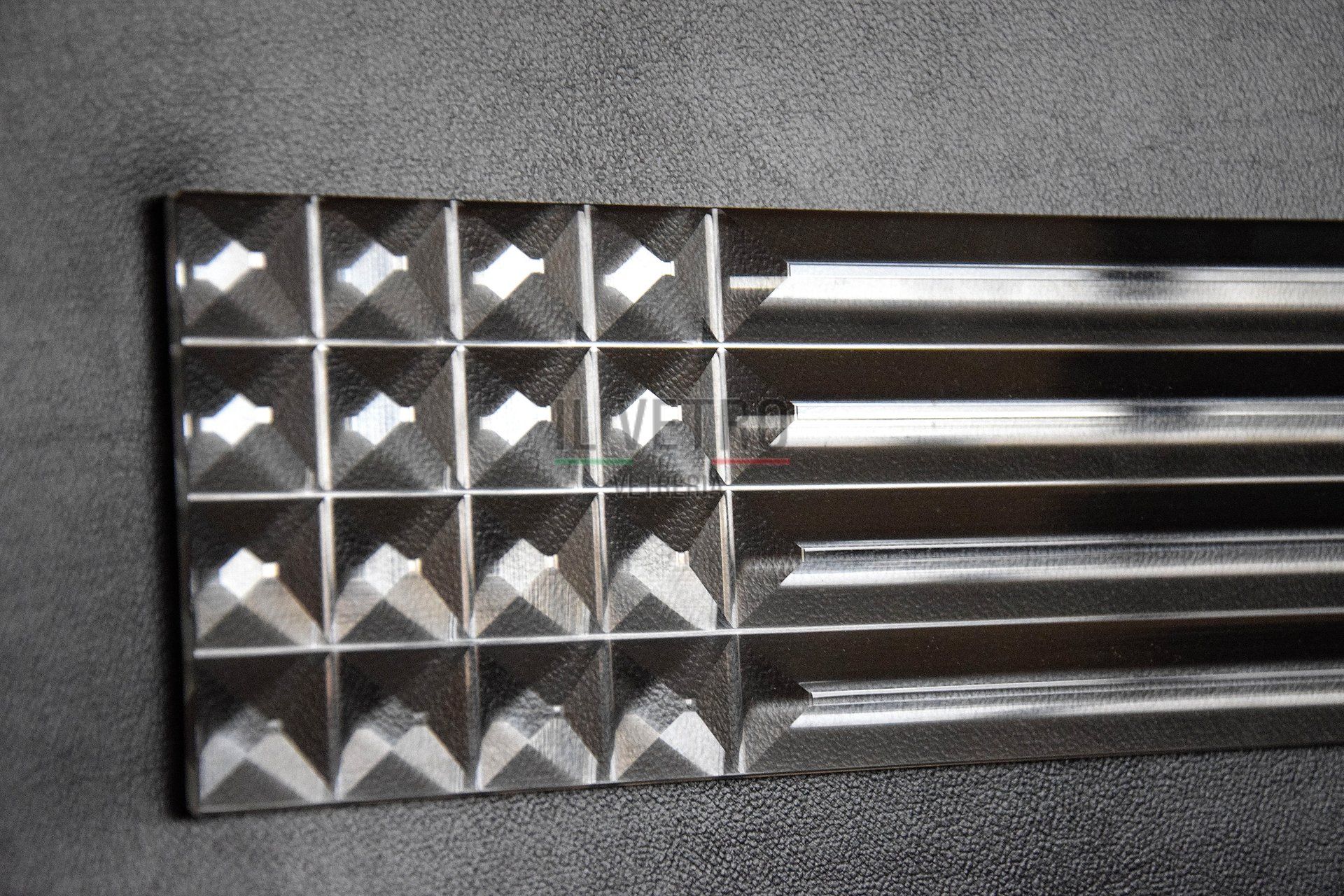

GRINDING - bevelling

Glass grinding is the process that allows to smooth and polish the glass after the cutting. There are several types of ground: from the basic one, that shines and smooths the edge of the glass (also called polished edge) to the more complex, like the surface bullnose, from which a rounded and shiny border is obtained, the rough edge that creates a smooth but opaque edge, and the sloping grinding with a variable angle. There is also the double and triple grinding (for thick glass) from which a rounded and shiny border is obtained, but with two or three consecutive bullnoses. Another possible processing is the chamfering, a particular operation through which both the edge and the surface of the glass are ground between a minimum of 5 mm to a maximum of 40 mm, depending on glass thickness.

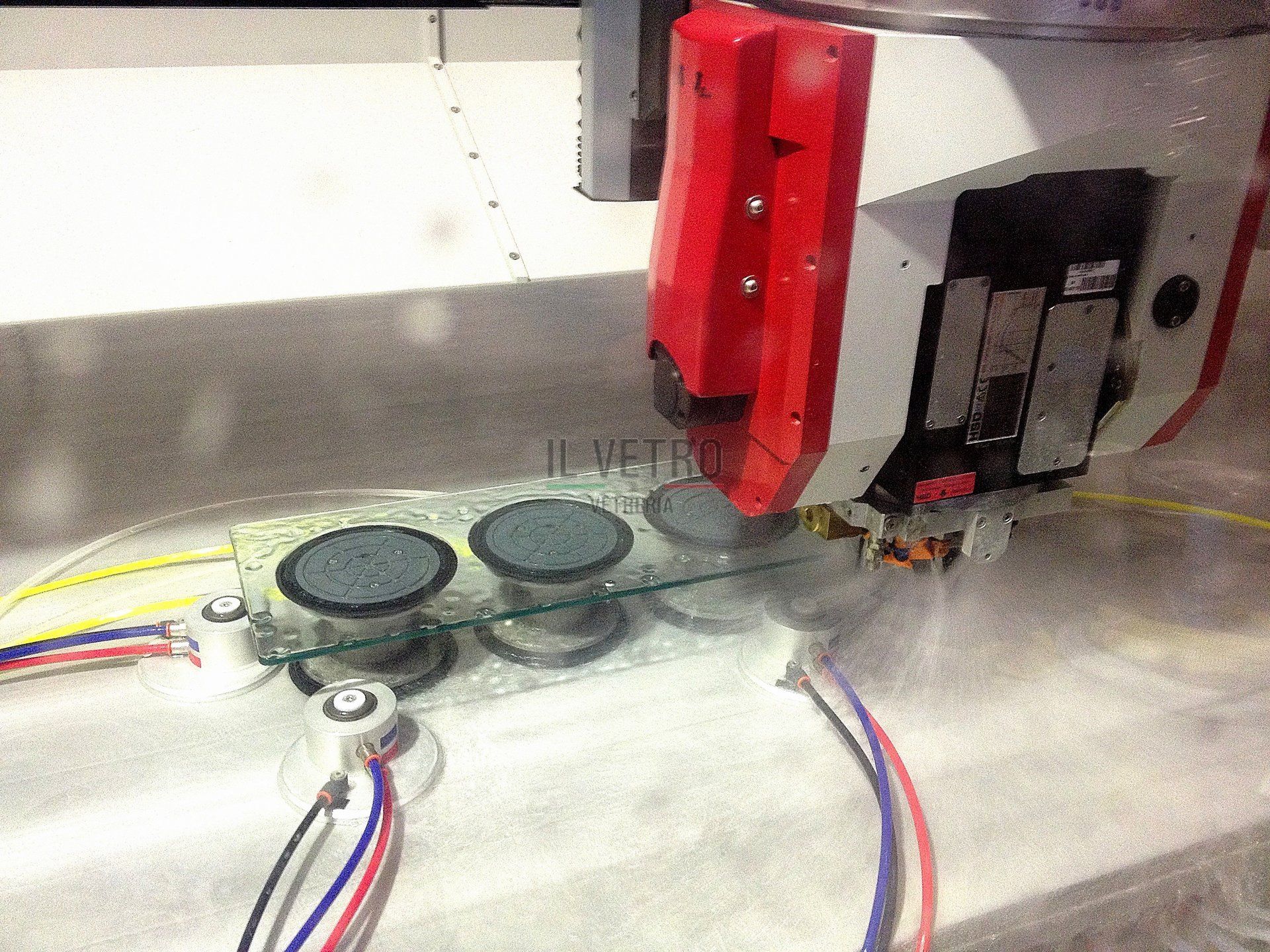

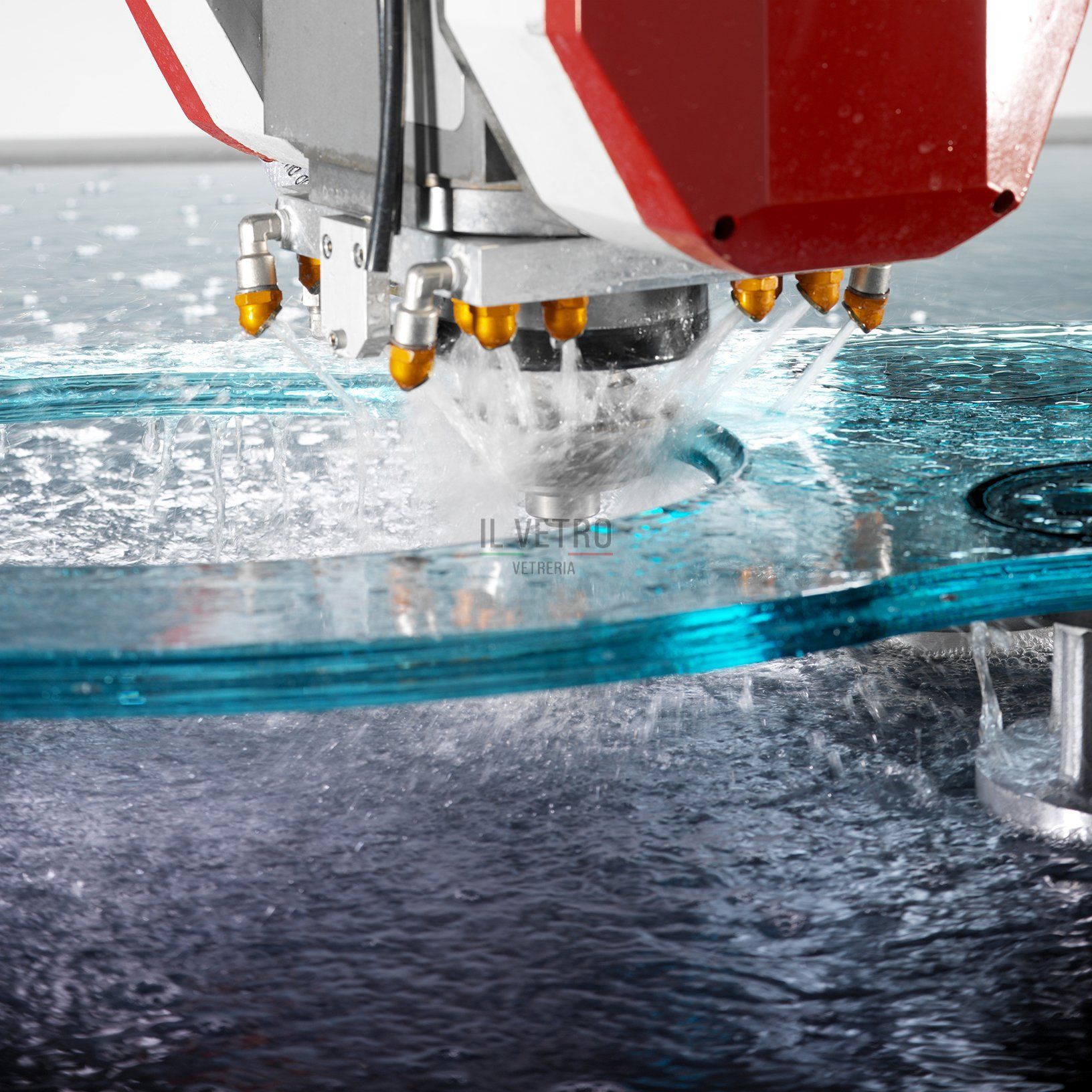

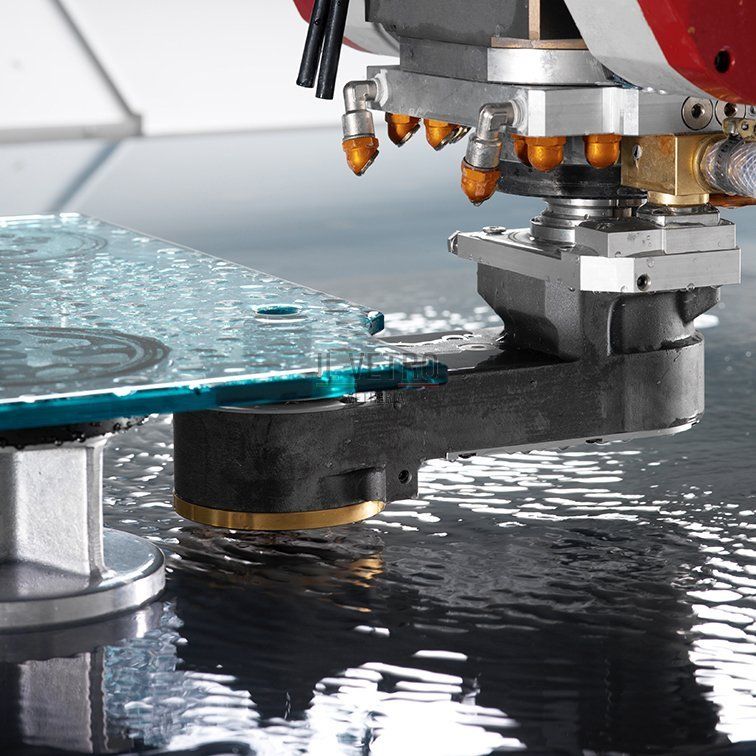

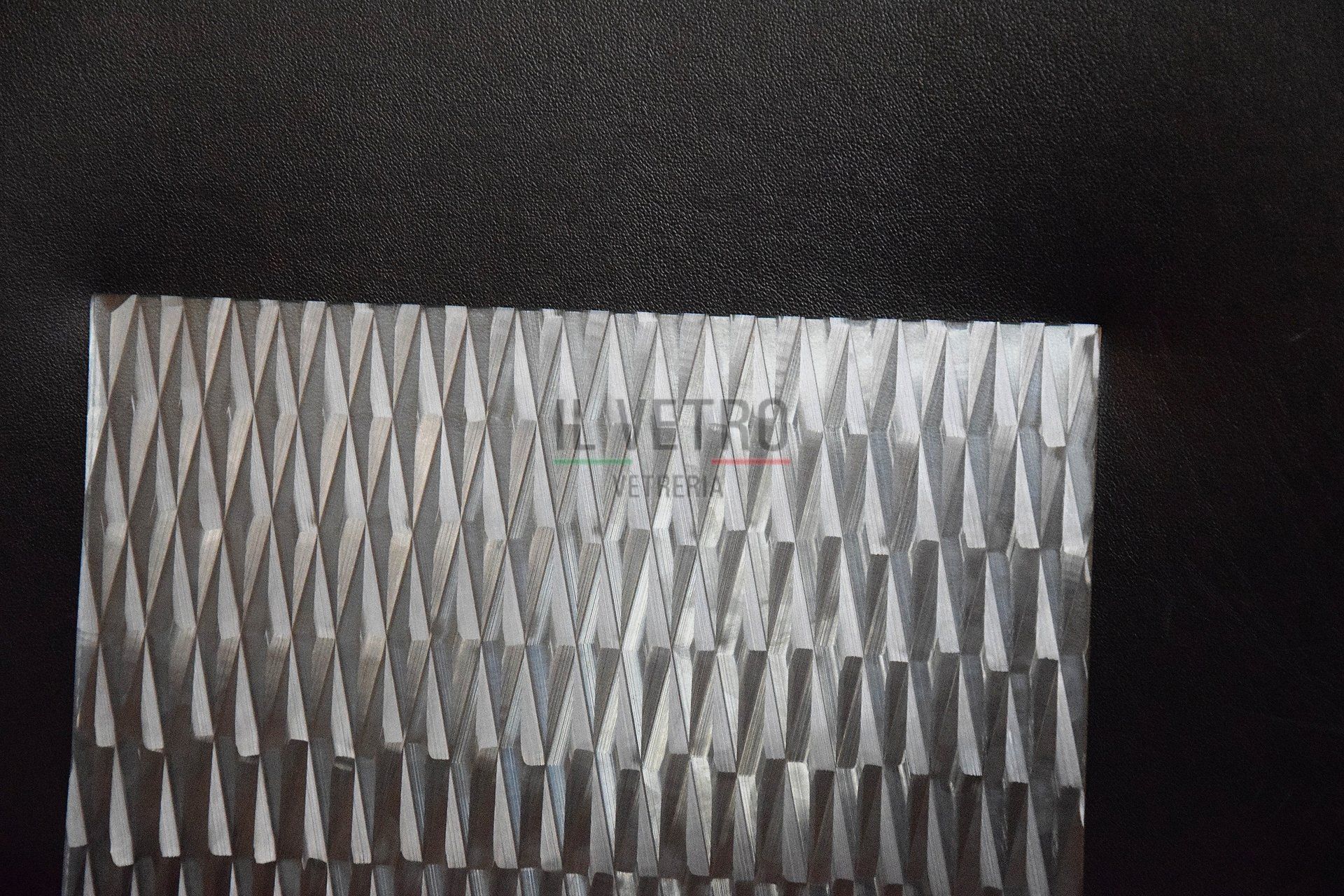

CNC (COMPUTER NUMERICAL CONTROL)

The equipment of Vetreria Il Vetro boasts three-and five-axis machining centres that allow, through an entirely automated process, to carry out V and U shape incisions on the glass surface as well as on the edges and in the centre of the slab. With this machine, it is possible to make holes, engravings, notches, slots, drawings, and mouldings (even inside the slab) according to the specific needs of the customer.

DRILLING

Holes in the glass are carried out both manually and by CNC machinery. For tempered glasses, there are some rules to follow to avoid the "opening" of the holes before the tempering process. The dimpled holes and the flaring on the curved glass of the wash basins are performed manually.

DIGGING

Digging is a kind of processing that allows making the glass surface concave. Modern CNC machines can achieve this process, but also by devices that are real "antiques," able to produce small size diggings such as those of the glass soap dish.

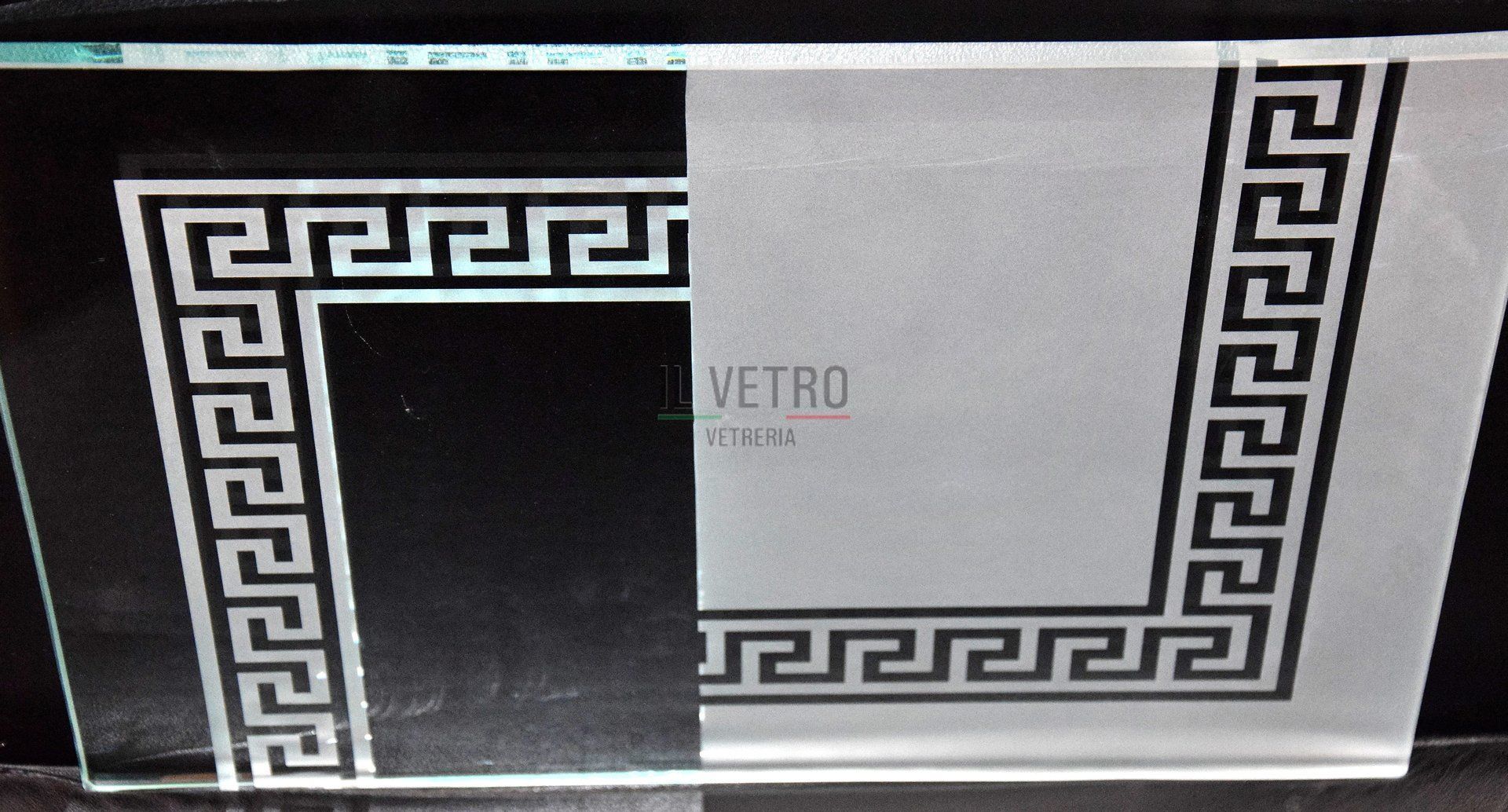

SANDBLASTING

Sandblasting is the process that allows total or partial glazing of the glass surface: it also allows to reproduce decoration, logos and other distinctive designs according to the needs of the customer. The opacification process is performed by a machine that causes the glass abrasion, making it opaque. Creating designs and decorations with transparent and opaque bases is possible.

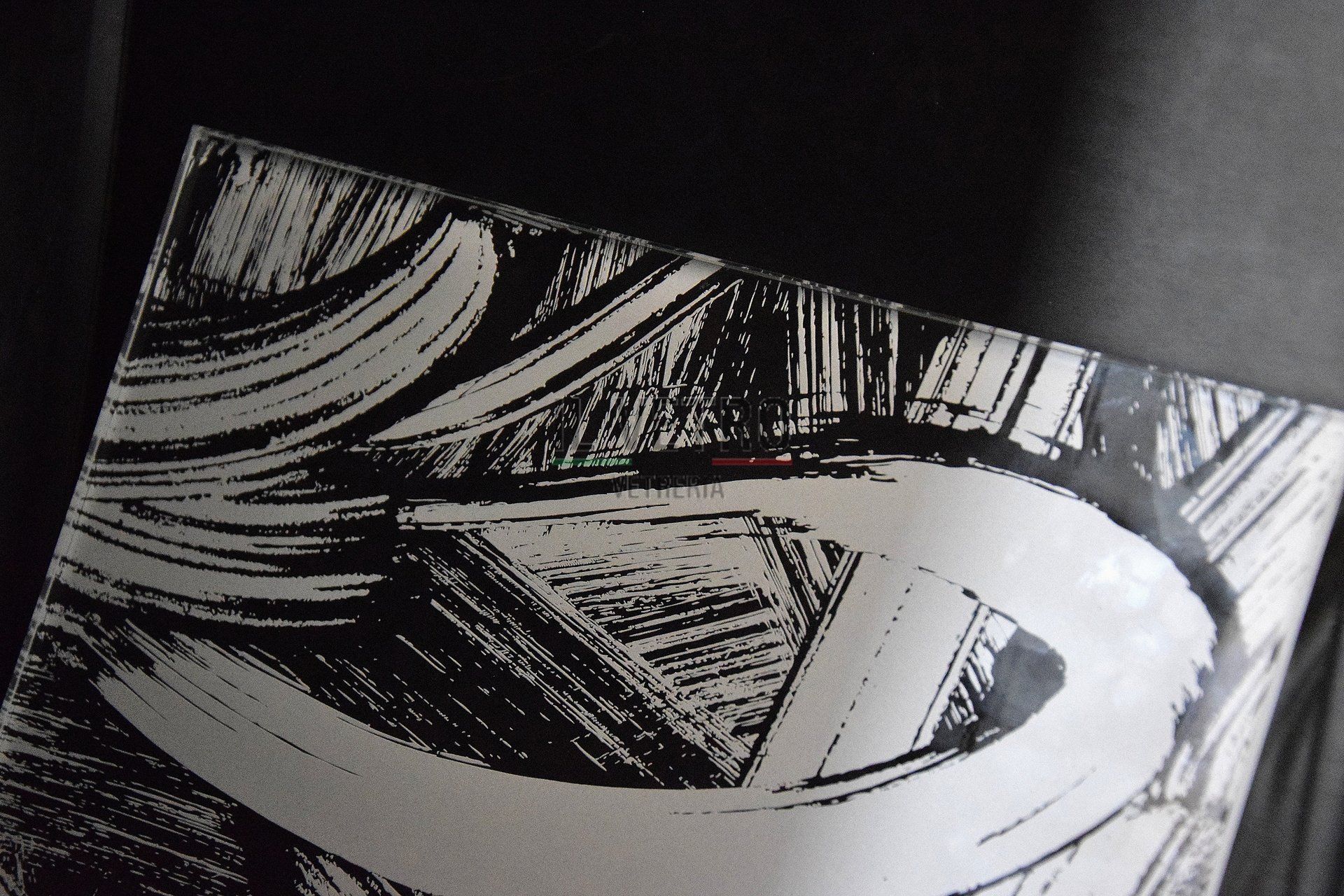

LASER

The laser engraving is a new and sophisticated engraving technique that allows making high-resolution graphics and images on the glass surface or within the glass itself. Engraving the inside of the glass enables reproducing three-dimensional images. This new technique can be combined with other processing, thus offering a wide range of customisable decorative solutions. Moreover, for amazing effects and a unique atmosphere, it is possible to light up the glass.

PAINTING

Glass painting is cold made, using a particular gun which guarantees a uniform colour spray. The paints used are all non-toxic and water-based. It is possible to realise standard colours as from our sample collection and RAL, PANTONE, and NCS colours. We can also create sample colours upon client request.

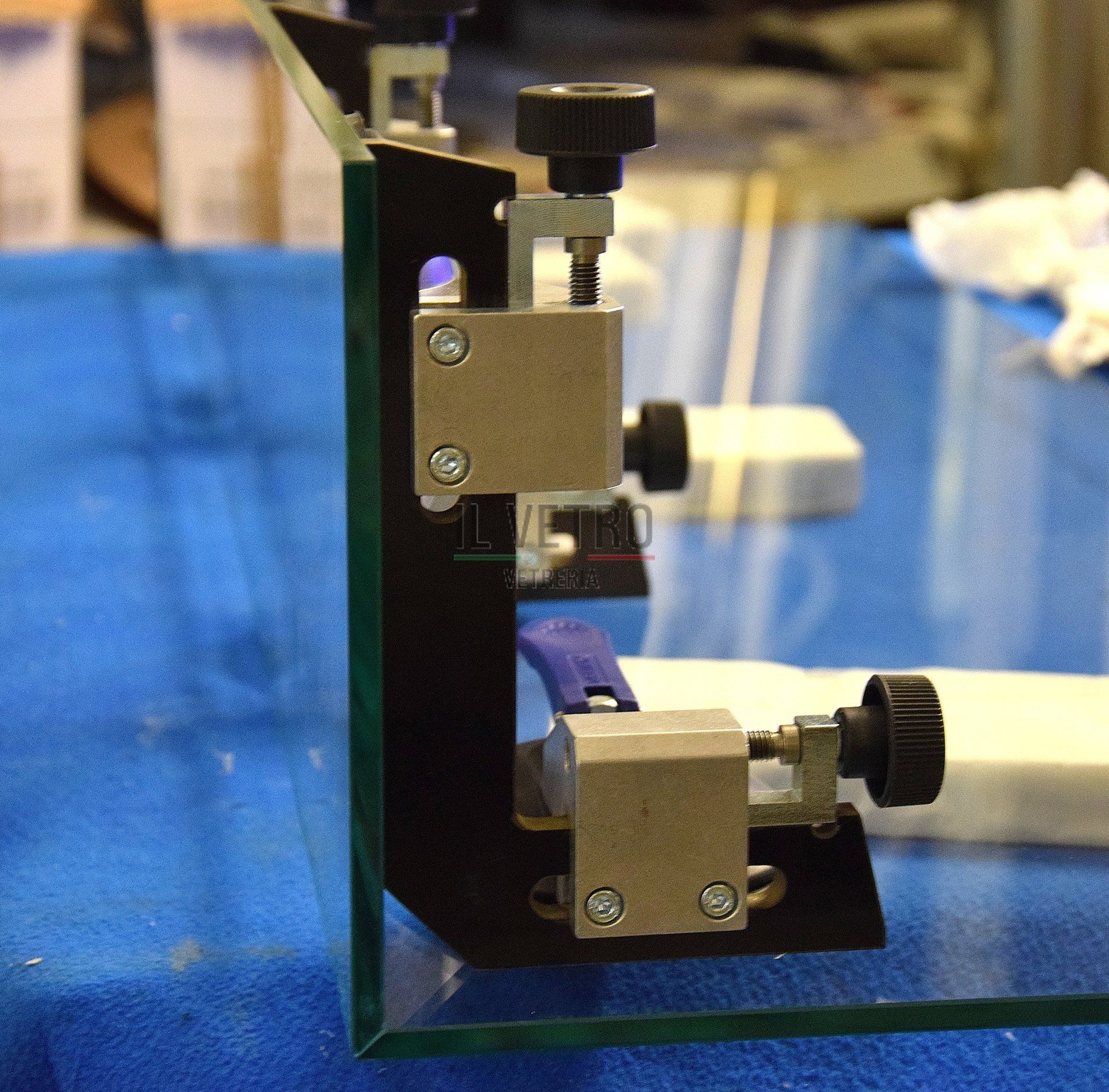

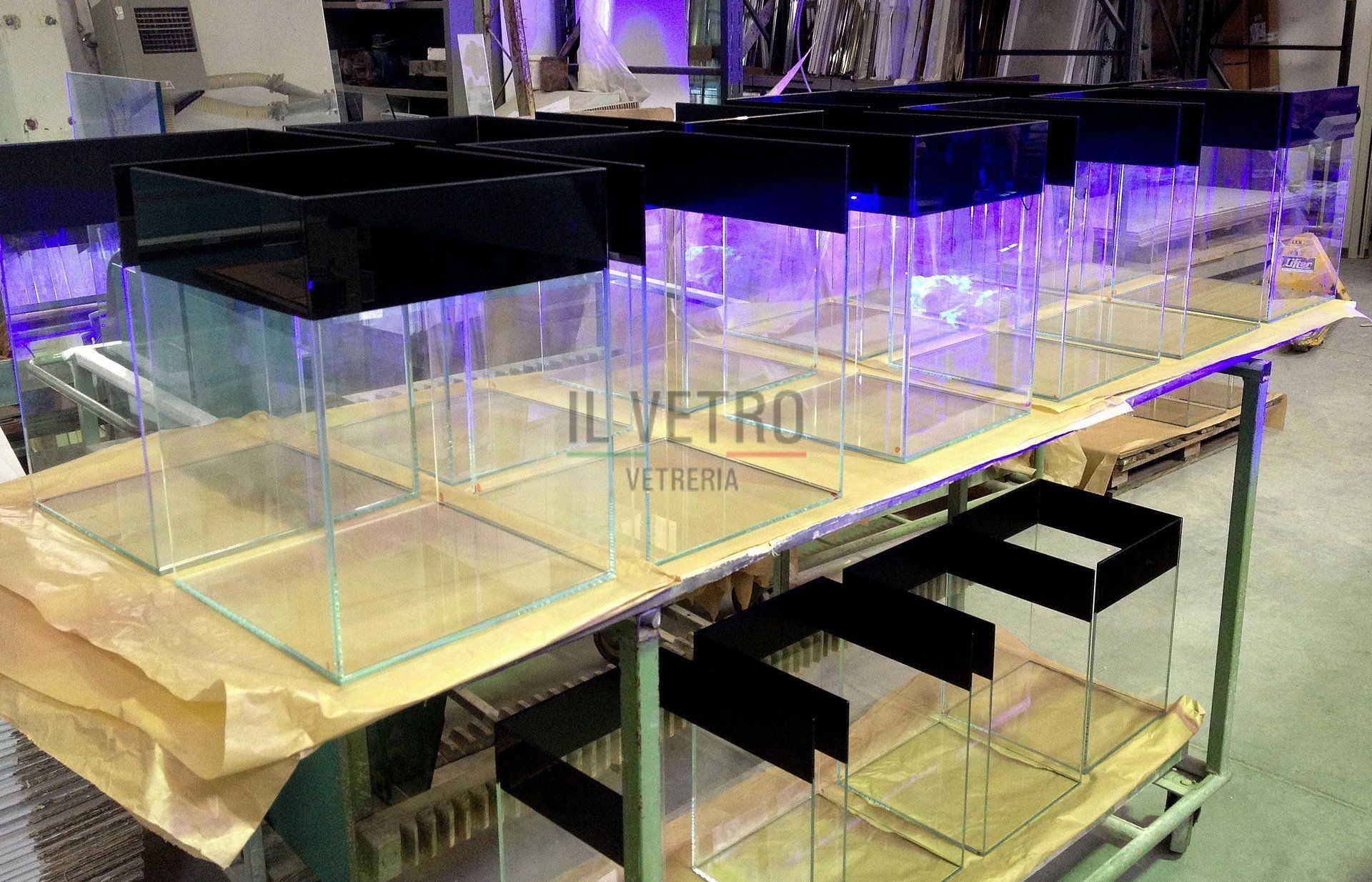

WELDING

This method allows the bonding of the glass slabs using an ultraviolet (UV) technique, creating a wide range of decorative items such as display cases, tables, consoles, or elements such as display cabinets, towers or display tables. The welding can be done either with 45° grinding or with flat trim; it is entirely hand-forged by highly qualified personnel. The process requires the use of an innovative adhesive that, when exposed to UV lamps bond quickly, ensuring the maximum of the tightness and becoming completely invisible.

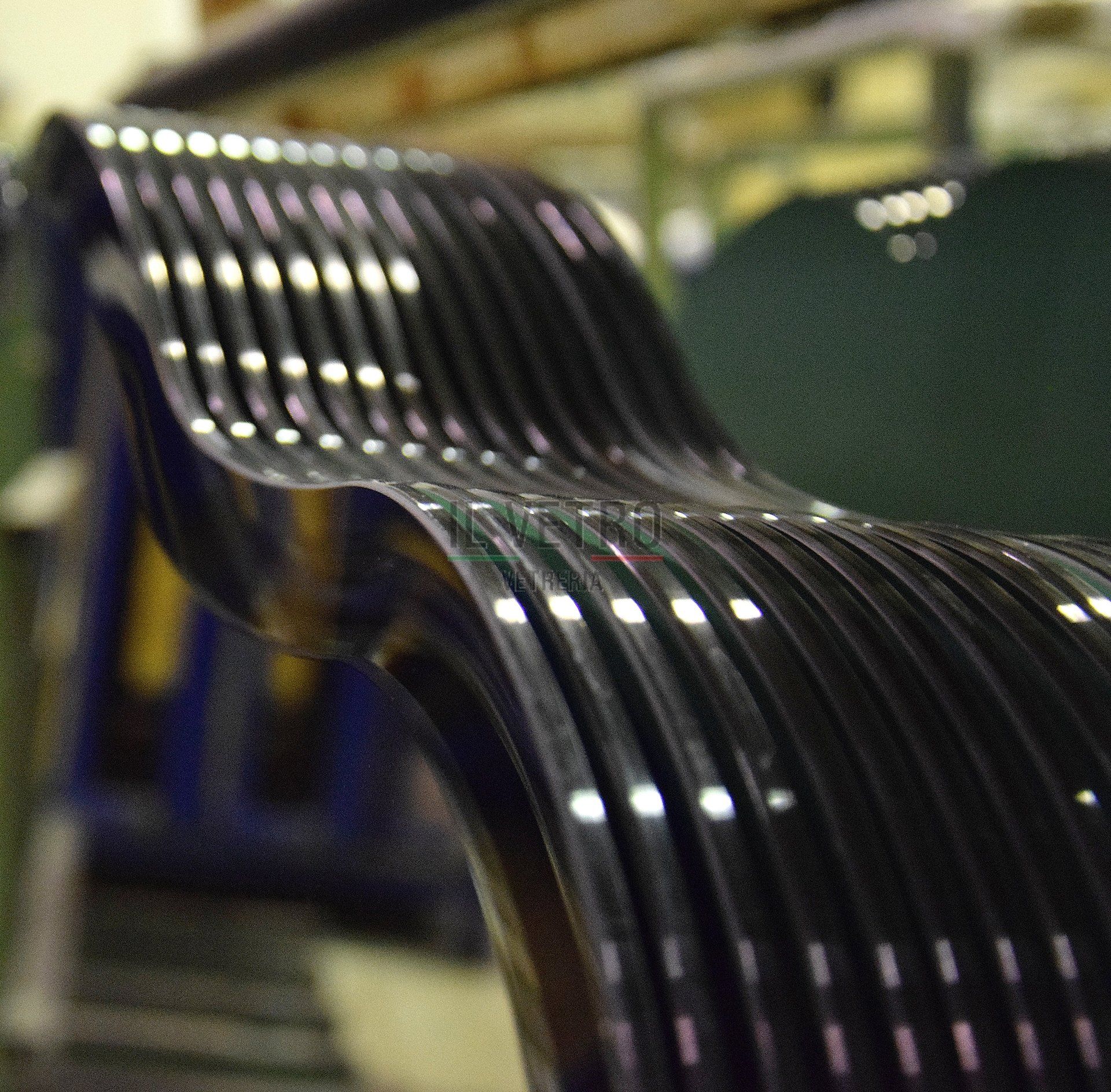

THERMOFORMING & BENDING

The thermoforming of the glass is achieved using a furnace sets up following specific requirements (temperature and timing), that can heat up the piece and to make it incandescent, thus starting the casting process. It is possible to control multiple bending in a single piece. Glass bending is obtained through an initial thermal process followed by a cooling one. For this process, a furnace that reaches a temperature of 600° C and some moulds to give to the glass the desired shapes shall be used.

TEMPERING

Tempered glass is obtained through a heating process that reaches 600° C and a subsequent and sudden cooling that drops the temperature to 300° C. This thermal shock causes a compression on the glass surface making it more flexible, durable and subject to stress as well as more mechanically resistant. Once tempered, if the glass breaks, it shatters into tiny fragments, not sharp, and hence totally harmless.

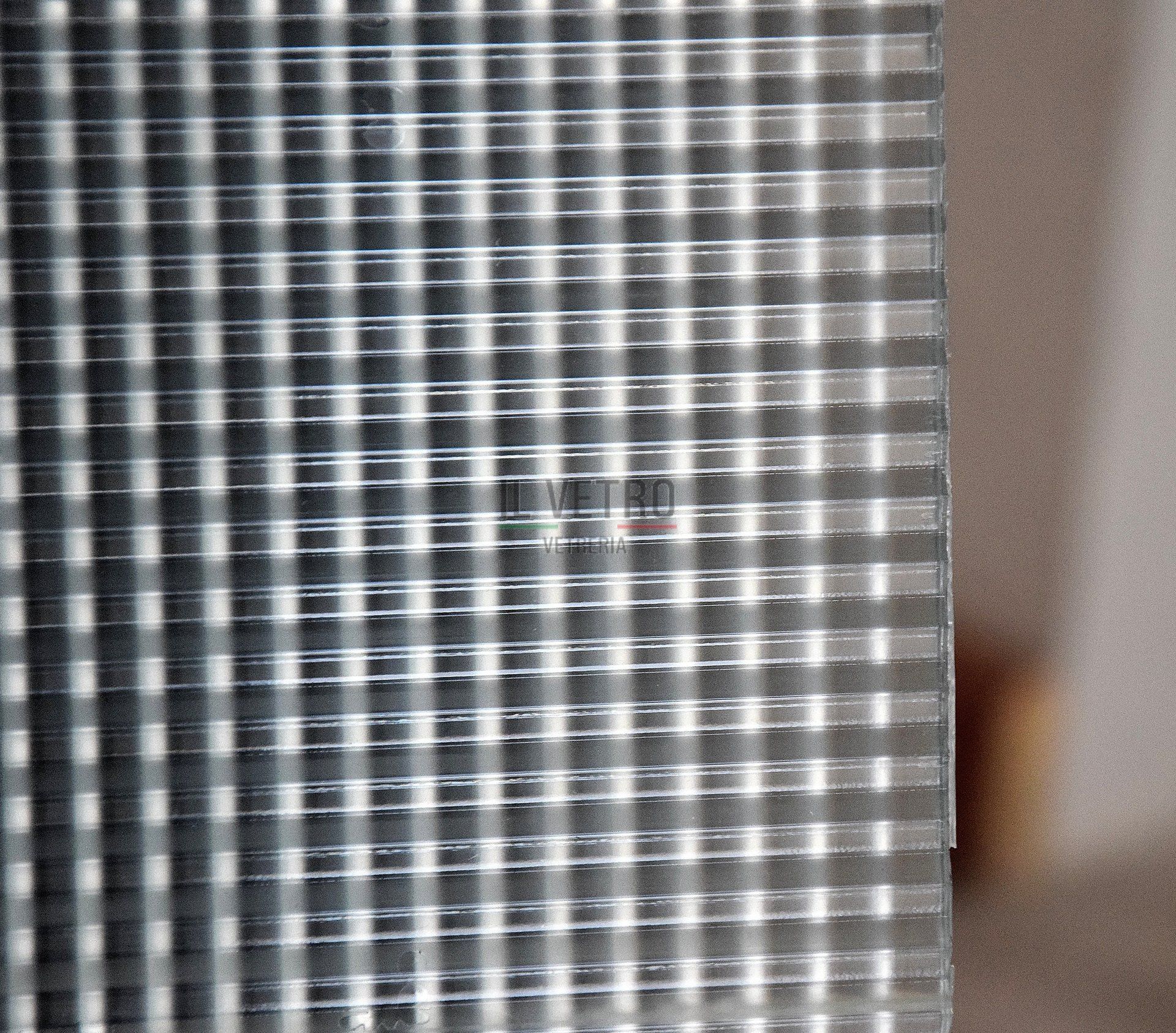

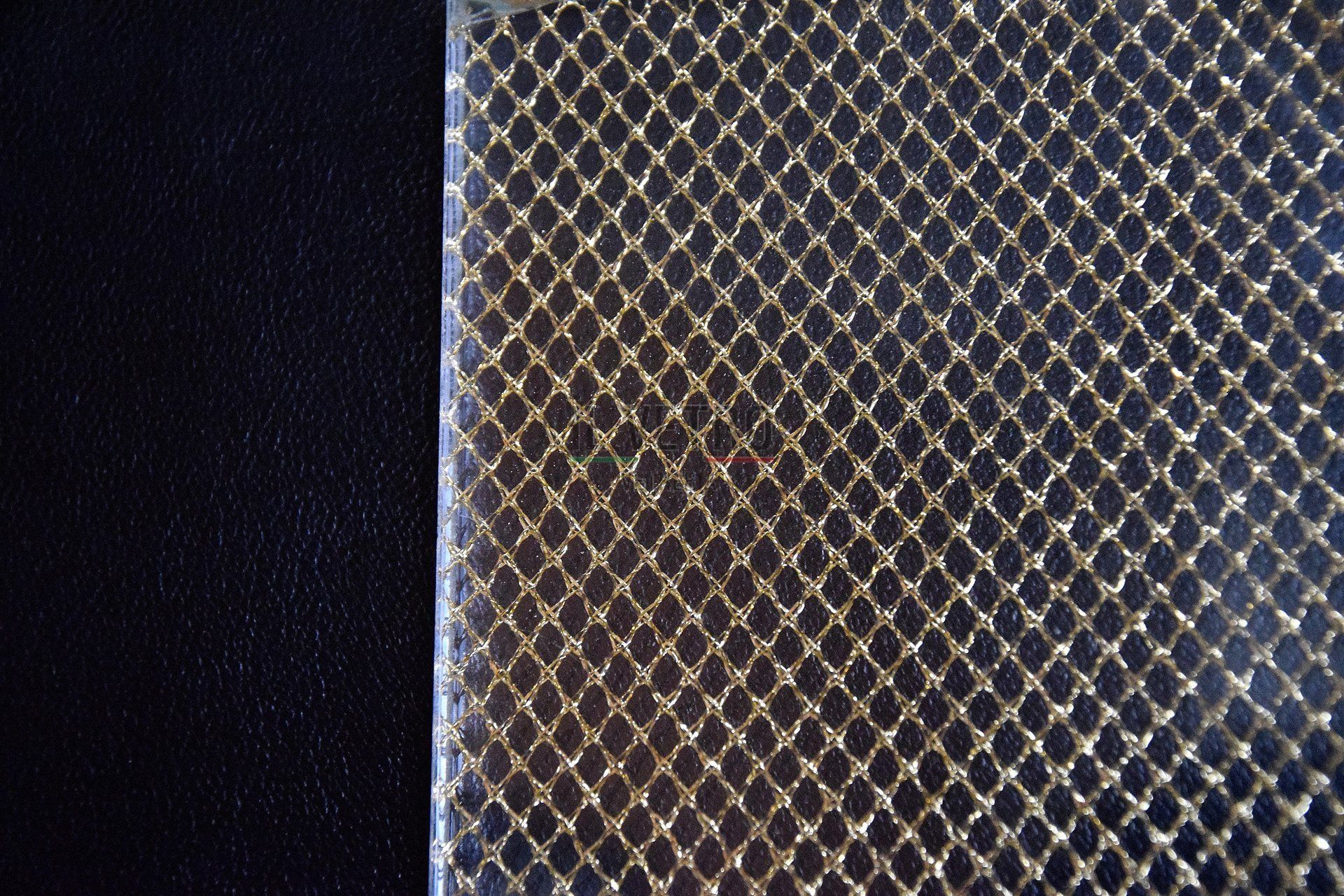

GLASS LAMINATION

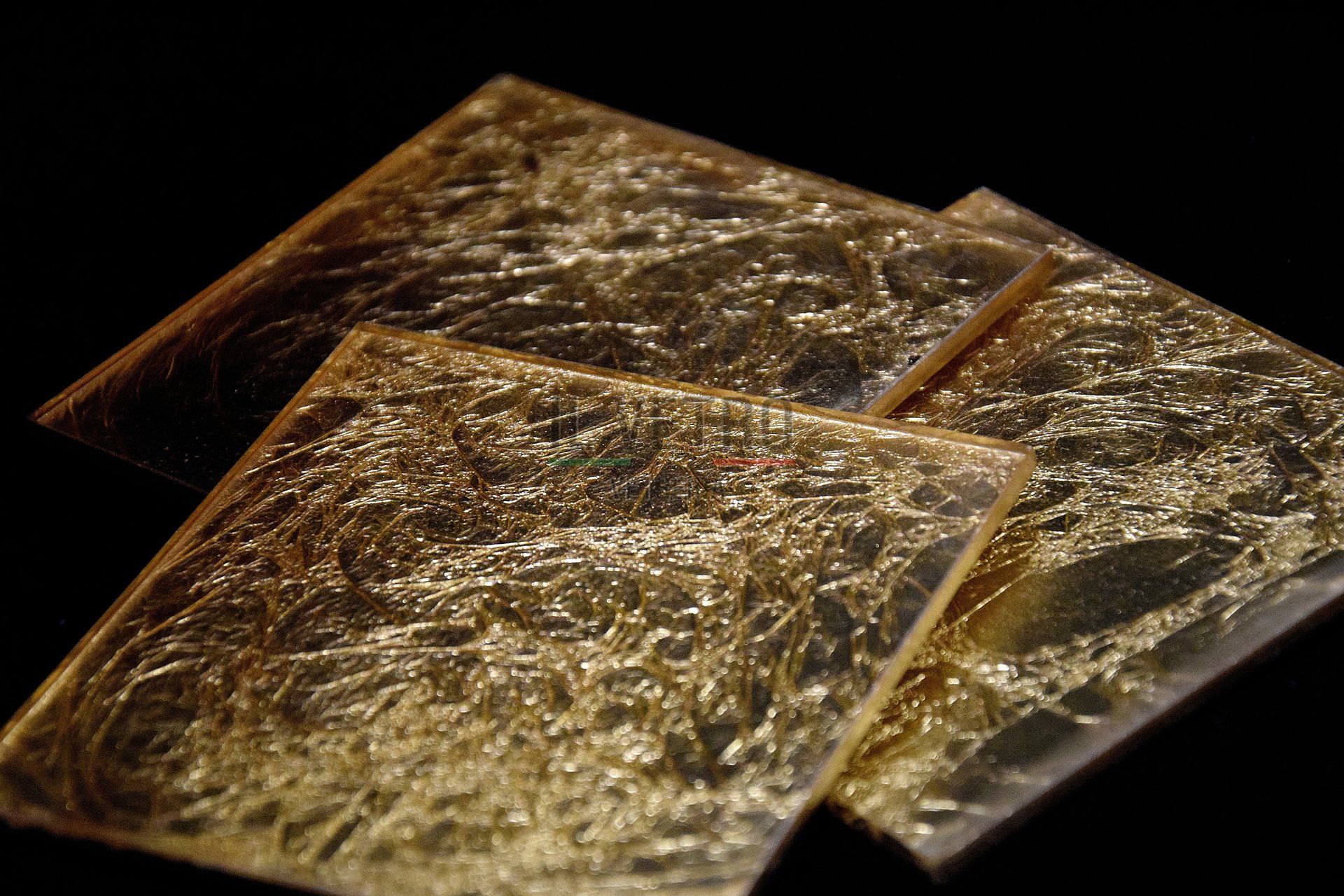

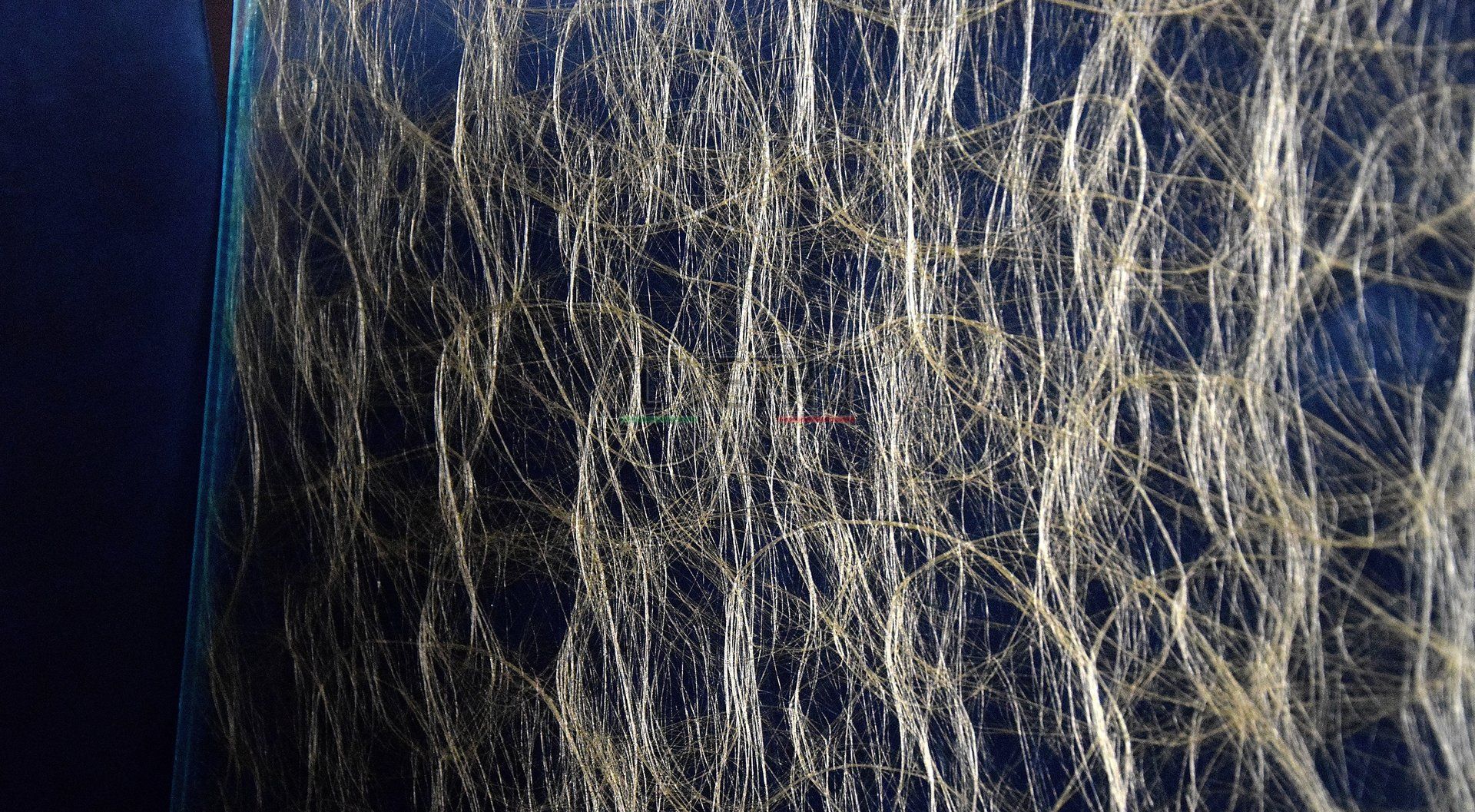

The glass lamination is obtained by joining one or more slabs to a plastic sheet in Ethylene Vinyl Acetate (EVA). The plastic sheet that joins the glass can have different thicknesses and colours depending on the needs. This technique allows the decoration of the glasses by placing inside the slabs textiles, digital prints, nets, metal canvases and other materials that can create designs and decorations. The laminated glass automatically become a "safety glass" as, in case of breakage, the plastic inserted between the two glasses acts as an adhesive by preventing the fall of the fragments.

DIGITAL PRINTING

Digital printing is used to reproduce high-resolution digital images on the glass. Through this technique it is possible to print many decorations such as textures, pictures and even material effects (wood, marble, etc.) making the glass a versatile material, able to satisfy any customer request or desire. The digital printing can also be combined with other processing, thus increasing the range of the final choice and making it possible to produce refined and innovative objects.

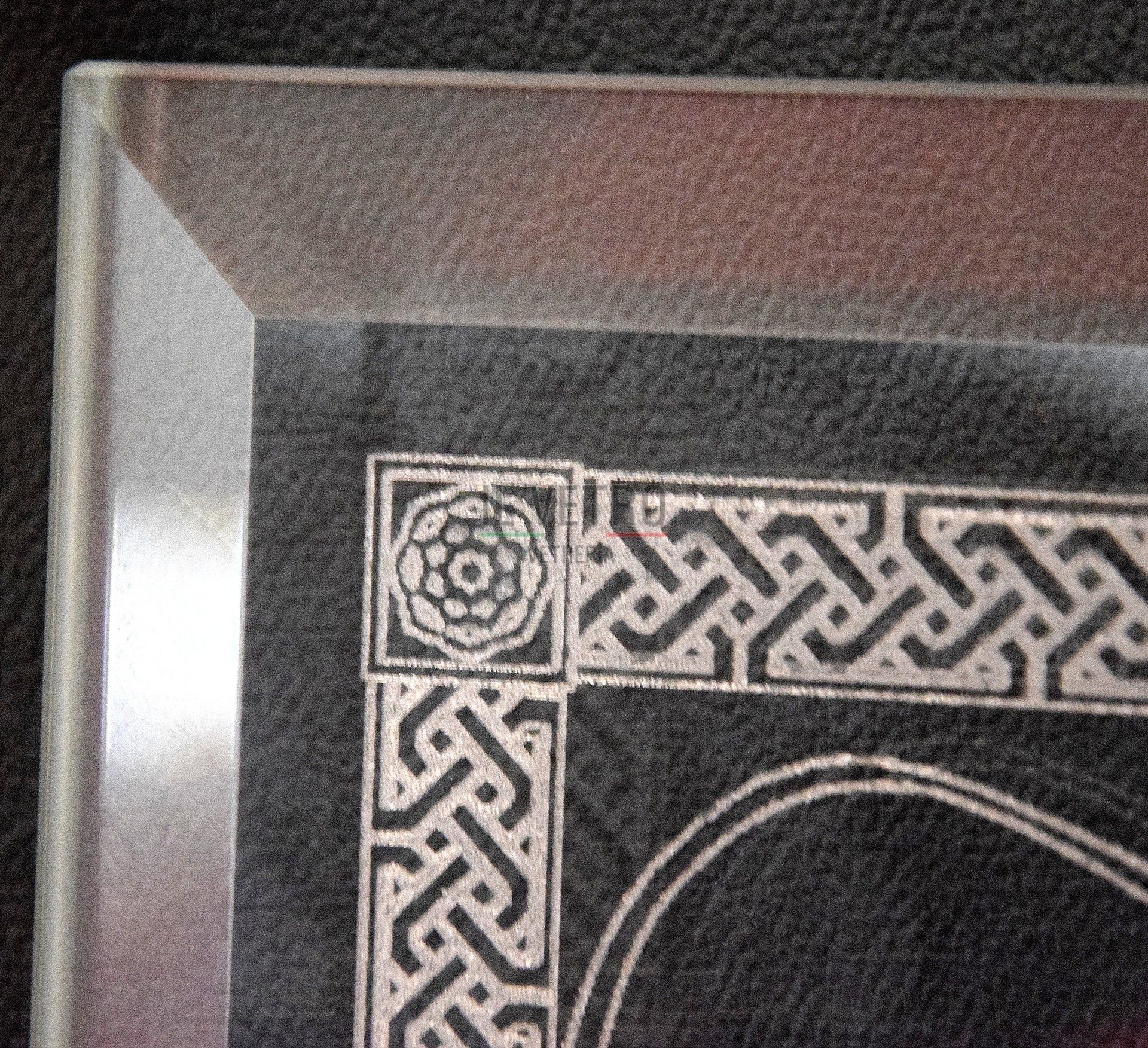

ARTISTIC CREATIONS

The company was born with the knowledge of a highly qualified team with thirty-years of experience in the field. Over the years, some young people have been introduced to practice, and now, they have gained an excellent knowledge. This know-how allows us to realise artistic pieces such as unique engravings on glass and mirrors, as well as gold and silver leaf decorations and other effects. A wide range of antique glass is also available.

ASSEMBLING

This specialized division of our company stands out from other traditional glass manufactures as it allows us, where needed, to offer a finished product to our clients, with delivery to the destination or to the site, to provide a quick and easy installation. The shower hinges are always pre-assembled.

PACKAGING

The packaging department ensures particular care in the packaging to minimise potential damages caused by handling. The staff uses customise and durable packaging along with the “Foam in Bag” technology, a particular way of packing made of polyurethane foam bags, which compensates both the empty spaces in the pack and protect and supports the product inside the box.